On March 1, the Danish astronaut Andreas Morgensen from the European Space Agency (ESA) will be replacing experiments during his mission aboard the International Space Station (ISS). He will be working on the third installation of the "Compacted Granulars" experiment in the Fluid Science Laboratory (FSL). Throughout the activity, he will be assisted by the operators of the Belgian User Support and Operations Centre (B.USOC), who will provide him with their expertise and assistance from their control centre in Uccle.

CompGran and microgravity

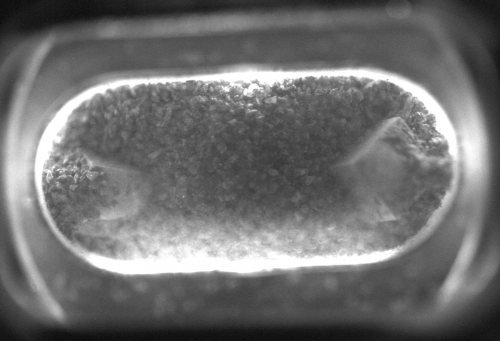

The Compacted Granulars (CompGran) experiment aims to analyse the behaviour of granular material in a microgravity environment. A CompGran Sample consists of a cell containing a movable piston and piezoelectric components, filled with granular material. As a result of collisions between the particles, they lose energy, which, under the effect of gravity, is accompanied by rapid sedimentation.

However, in microgravity, the loss of particle energy can be studied independently of the sedimentation process. By compressing the sample with the piston and activation of the piezo, a variety of observation conditions can be created. At high enough density, the granular system stabilises and the majority of particles form permanent bonds.

Nevertheless, a few particles, known as "rattlers", remain with either no contact or too few to become completely fixed. These grains may continue to exhibit certain movements, even after the overall system has come to a halt. In order to obtain uniform results that can be correlated with computer models and theory, high quality and prolonged microgravity is required. This condition will also ensure that the behaviour of a granular system can be monitored over its entire energy range, from the early stages of dense cooling over slow glassy dynamics upto complete arrest.

Say "Cheese!"

The current CompGran mission uses a total of four samples, three of which are filled with polystyrene seeds 0.14 mm in diameter and one of which is filled with a material that mimics lunar dust. The difference between the three polystyrene samples is that two of them have differently shaped piezoelectric elements, while in the third the seeds are coated with a special aerosol coating that changes their behaviour when subjected to higher densities.

A surveillance camera in the Fluid Science Laboratory (FSL) records black and white video footage of the sample cell. At the same time, a laser, a line camera and two CorrTectors facilitate the use of new diagnostics methods, including Diffusing-Wave Spectroscopy (both transmission and backscattering) and Speckle-Visibility Spectroscopy (enabling time-resolved correlation). The FSL provides power and data management capabilities for the encapsulating Experiment Container for remote operations and transmits images and scientific data to the ground.

Support from the Earth

The Belgian USer Support and Operations Centre (B.USOC), hosted by the Royal Belgian Institute for Space Aeronomy (BIRA-IASB) in Brussels and supported by Space Applications Services, is responsible for the implementation of select European payloads on board the International Space Station (in particular FSL and CompGran), on behalf of the European Space Agency.

It acts as a link between scientists and the ISS environment, and is responsible for preparing and operating these experiments, as well as distributing the raw scientific data from the experiment to the Science Team. The B.USOC operators are in contact with other ground control stations across Europe to ensure that these experiments are executed as expected and according to the needs of the scientists.

The experiment is the result of a collaboration between scientists coordinated by Professor Matthias Sperl (DLR).